According to the U.S. Department of Housing and Urban Development, for every $1 spent on preventive maintenance, you can save up to $4 in future repair and replacement costs.

Most people already know that preventive maintenance (PM) brings a host of benefits compared to reactive maintenance, including:

- Lower Long-Term Costs

- Reduced Downtime

- Extended Equipment Life

- Increased Safety

- Higher Operational Efficiency

- Less Overtime and Emergency Labor

- Improved Asset Reliability

The list goes on—but you get the point.

So, the real question is: With so many compelling reasons to adopt a PM program, why do so many schools and institutions still struggle to implement one?

After speaking with thousands of operations professionals over the years, the answer usually comes down to two things: time or money—or both.

Here's how we often hear it expressed:

- Tight Budgets or Funding Gaps – Are you mostly running to failure?

- Limited Staff & Resources

- Lack of Training or PM Knowledge

- Outdated (or Worse—Nonexistent) CMMS Systems

- No Asset Inventory or Baseline Data

- Aging Infrastructure

- Competing Priorities

We know you're likely juggling multiple critical needs, and sometimes PM tasks take a backseat—until there's a crisis.

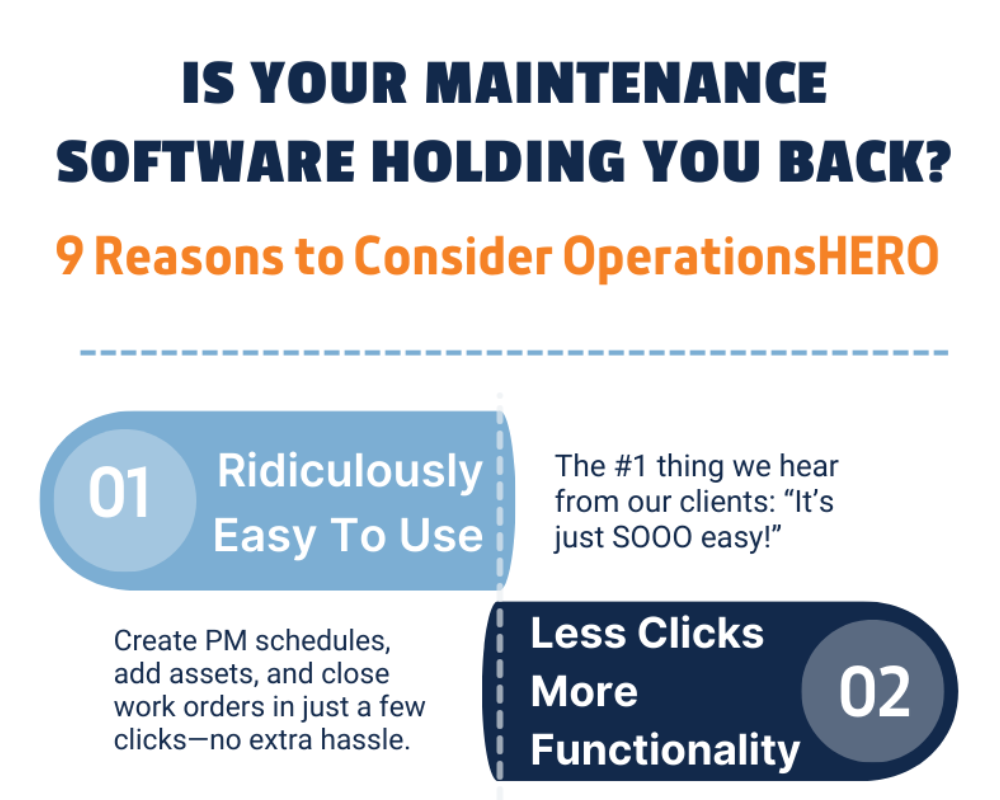

Good News: OperationsHERO Can Help

Rome wasn't built in a day, and we can't solve every barrier to PM in one blog post. But we can show you how AI and OperationsHERO can help tackle three of the biggest blockers:

- Lack of training and knowledge

- Outdated or nonexistent CMMS systems

- No asset inventory or baseline data

How AI Enhances Preventive Maintenance Task Books

Think of a task book as your master checklist—who's doing what, when, and how. When powered by AI, it becomes much more than a digital sticky note. It becomes a learning system.

Here's how AI supercharges your PM program:

Smart Scheduling

AI analyzes historical data to recommend optimal intervals. Instead of rigid weekly or monthly timelines, it adapts based on actual usage, wear patterns, and environmental conditions.

Anomaly Detection

Using sensor data, AI can flag patterns that indicate early signs of failure—allowing for intervention before scheduled maintenance is due.

Auto-Populated Tasks

Need to create maintenance plans for dozens of machines? AI can auto-generate tasks based on manufacturer specs, usage history, and best practices in your sector.

Resource Optimization

AI can assign tasks based on technician availability, skill level, and past performance—ensuring the right person is on the right job at the right time.

What Types of PM Intervals Should You Use?

Interval planning is everything—and AI helps make it both smarter and more flexible. The main types include:

- Time-Based: Scheduled at fixed intervals (e.g., weekly, monthly). Best for predictable tasks like HVAC filter changes.

- Usage-Based: Triggered by metrics like mileage, hours run, or cycles completed.

- Condition-Based: Initiated when sensors detect that a component is nearing failure thresholds.

- Predictive: The gold standard—AI predicts failures before they occur, based on trends and real-time data.

Blending these strategies creates a responsive system that evolves with your operation.

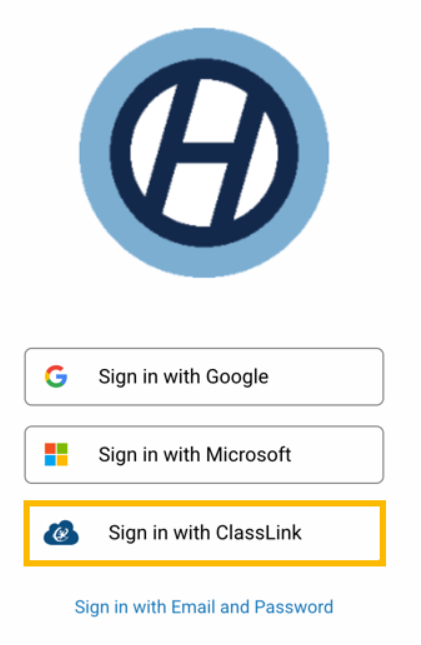

Getting Started (It's Easier Than You Think)

You don't need to be an AI expert to get this going. With OperationsHERO, AI is built directly into the platform—no add-ons, no data science degree required.

Here's a simple roadmap:

- Audit Your Assets: Start with a list of your equipment, current maintenance tasks, and any failure history.

- Choose an AI-Ready Platform: Look for a system that offers automation, data integration, and machine learning. (We obviously recommend HeroHQ!)

- Start Small: Pilot with one facility or asset type. Let the AI learn, then scale it across your campus or district.

- Train Your Team: The best tools are only as effective as the people using them. Keep onboarding simple, offer support, and celebrate small wins.

Why It's Worth It

AI-powered preventive maintenance doesn't just cut breakdowns. It fosters a culture of foresight, builds team confidence, and—perhaps most importantly—saves real money.

With smarter task books, proactive scheduling, and fewer emergencies, maintenance transforms from a cost center into a strategic advantage.

Ready to get started? We'd love to show you how OperationsHERO makes it ridiculously easy to launch a modern PM program powered by AI. And yes—the payoff is real.